Baosteel

Baosteel, a stated-owned company headquartered in Shanghai, China, is one of the largest steel companies in the world. It manufactures a wide range of steel products distributed to several different industries worldwide.

Innovative technology

In 2019, Baosteel took advantage of the Lut demonstration platform and performed a complete, long-term, evaluation of the Lut 2.0. The wall thickness gauge was installed at the exit of the mandrel mill at Baosteel’s seamless pipe factory in Baoshan, China. The mandrel bar inside the tube at this location makes the use of a radiometric-based system impossible. Encouraged by the excellent reputation of Tecnar’s latest laser ultrasonic technology and with the aim of acquiring new manufacturing insights, Baosteel ran a project using the Lut 2.0 SPF in their Shanghai plant for a few months.

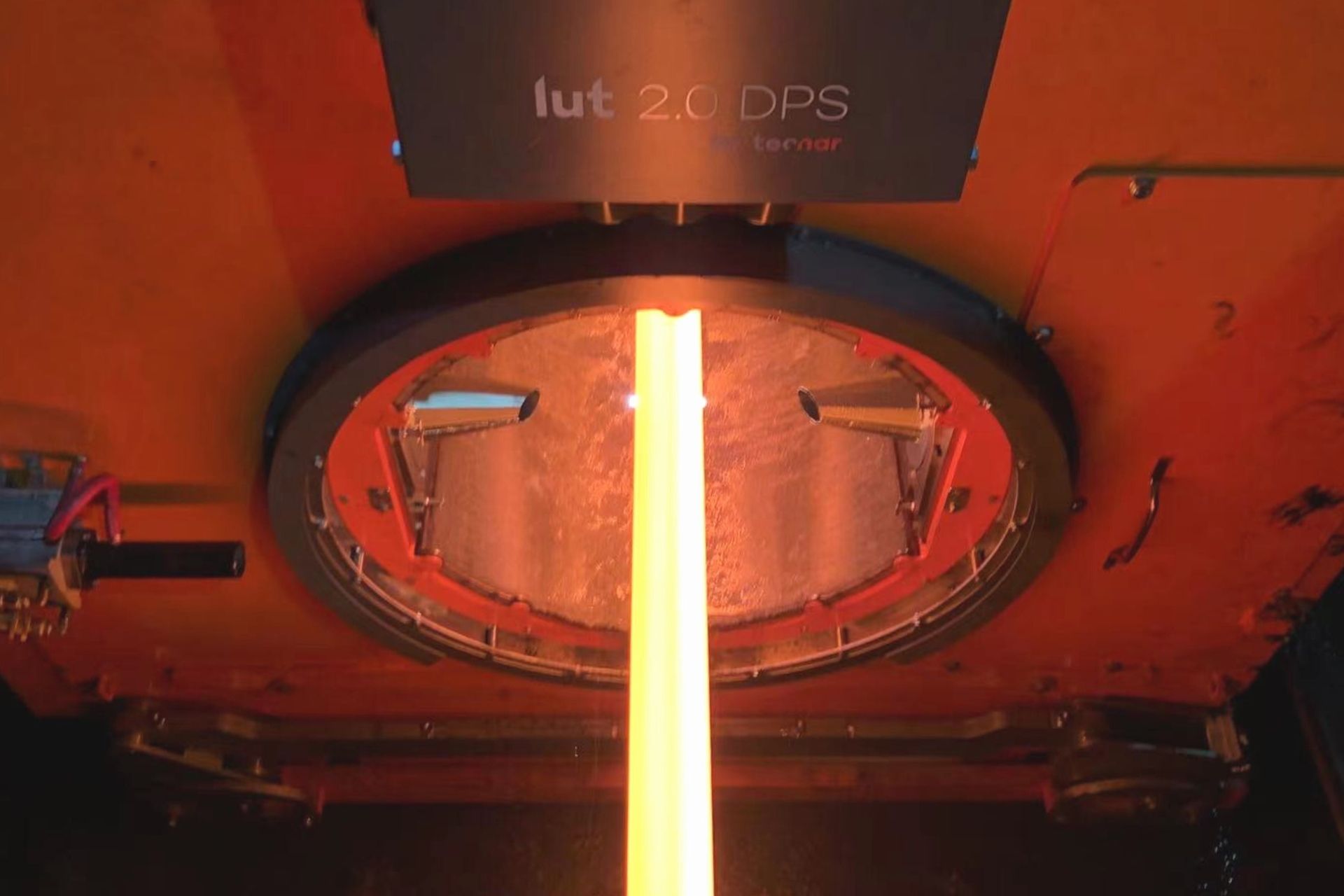

In 2020, based on the positive results of this demonstration, Baosteel adopted the laser ultrasonic technology and purchased a Lut 2.0 DPS after a competitive tender process. The installation was completed in December 2021. The Lut 2.0 DPS has since been routinely providing additional insight into the rolls settings of the mandrel mill.

Floating mandrel mill

Earlier insights

Highly accurate

Immediate impact on productivity and quality

During the demonstration period, the Lut 2.0 SPF achieved an accuracy level of over 50µm and displayed a very high level of industrial availability. The data gathered by the Lut 2.0 during the trial period led to new observations about the behaviour of the tube mill. Mean wall thickness deviations and eccentricity were of particular interest and investigated in depth by the team at Baosteel. Using information from the Lut 2.0 advanced thickness profile analysis, Baosteel could identify the root cause of wall thickness variations, develop better ways to control thickness and achieve a higher quality final product.

Talk to our expert today

Leave your details so our experts can contact you. Our team will answer all your questions and suggest the best solution for your needs.