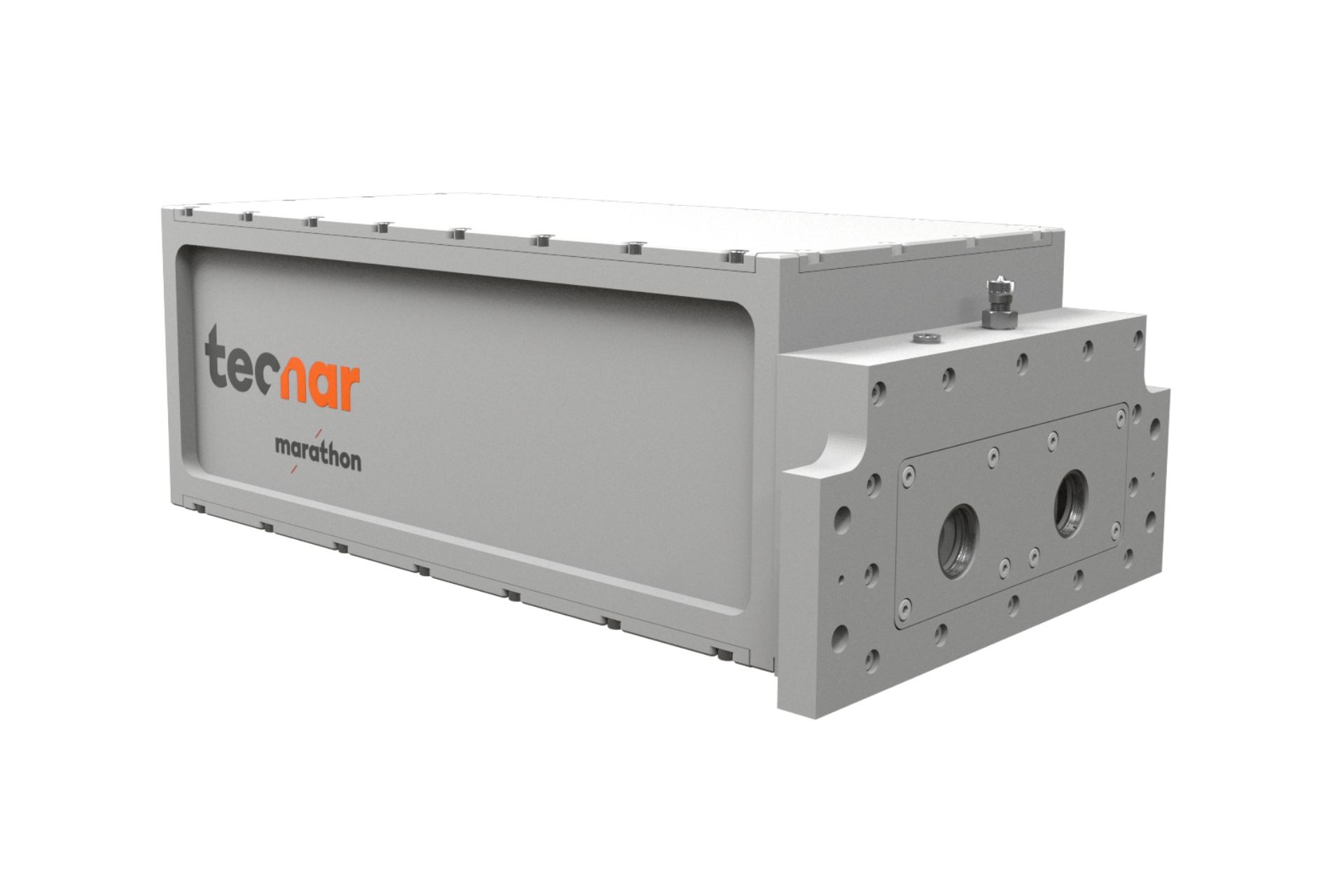

Maintenance plan

Predictability is key to managing the operational costs of a seamless line. Our service plan gives plant managers the peace of mind of knowing that they’ll never incur unexpected repair costs.

- Flat-rate, all-inclusive, 5-year plan

- Insures > 98% industrial availability