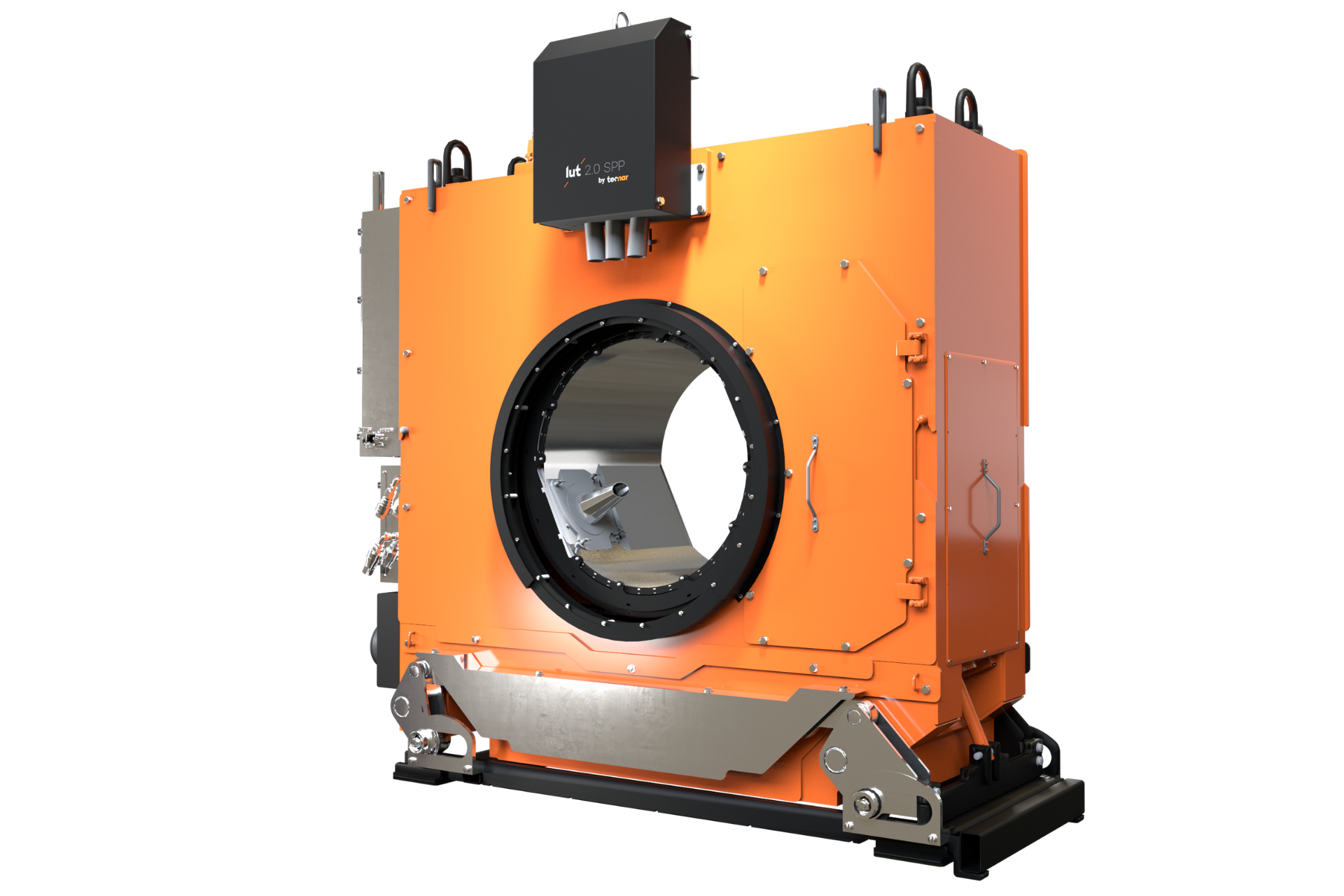

Lut 2.0 SPP/

Single Probe Positioning

The Lut 2.0 SPP for longitudinal mill

The Lut 2.0 Single Probe Positioning is best suited for longitudinal milling processes such as:

- Sizing mills

- Stretch reducers

- Retained mandel mills

The Lut 2.0 SPP positioning unit can set the measurement probe at any fixed angular position around the tube. The resulting wall thickness profiles help operators adjust rolling mill operating parameters.

Single probe positioning device

- Position probe at any fixed angle

- Not affected by a mandrel. Can be installed directly at the exit of the mill.

- Small footprint with as little as 1200 mm x 3000 mm of floor space is required

- No tube guiding required

- Built to sustain direct tube impact

- Integrated turnkey equipment with all support systems included.

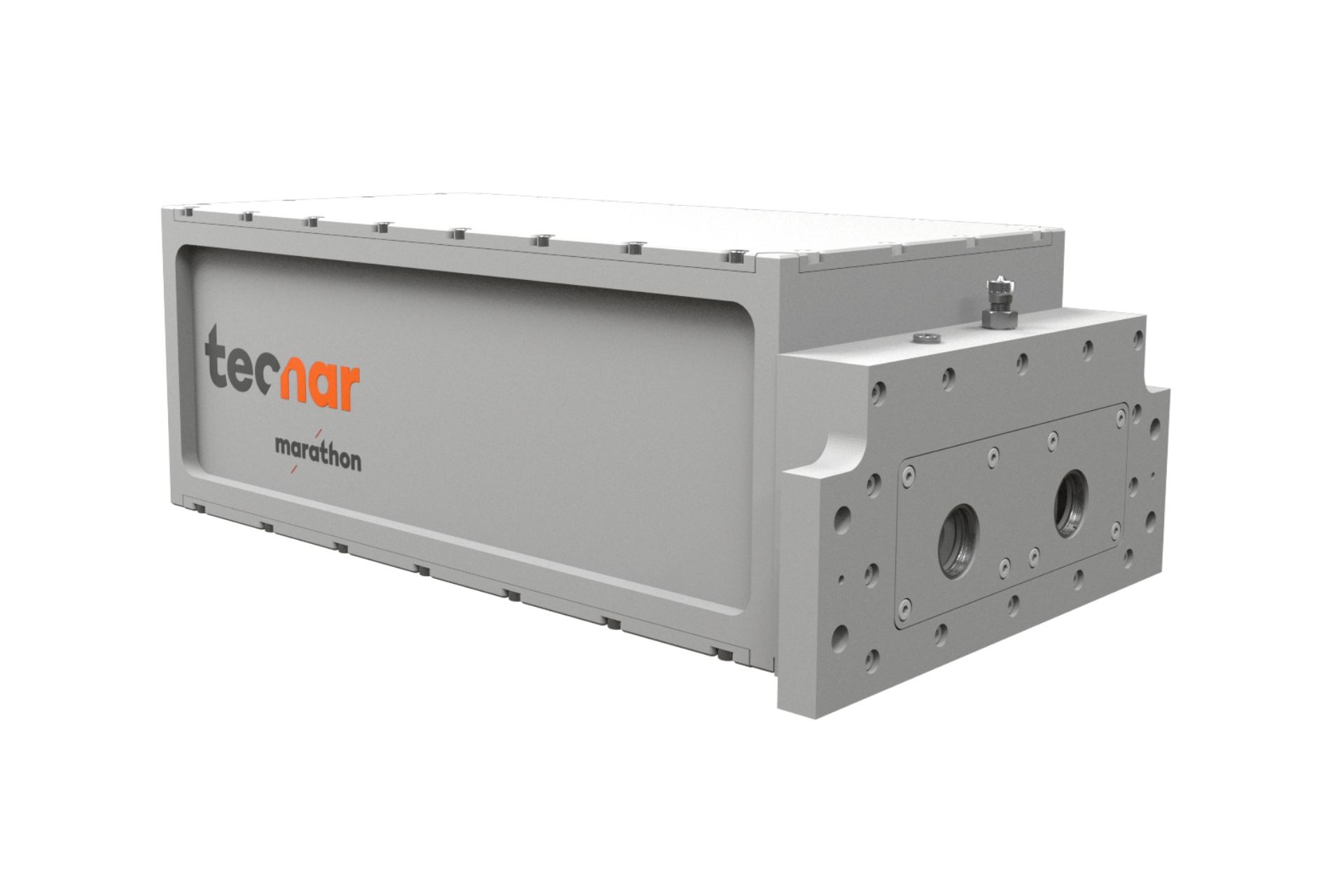

Key hardware advantages

- Marathon™ laser, with a diode lifetime of 6 billion shots, does not require any regular maintenance

- Durabeam™ fully sealed optical assembly for years of maintenance-free operations

- PDL™ provides a wide working margin (>350mm) so the Lut 2.0 can operate at a safe distance from the tube

- TWM™ high-sensitivity detector is naturally immune to ambient vibrations.

Intuitive user interfaces

The Lut 2.0 thickness gauge continuously monitors tube production to attain better mill yield. Through the user interface, operators have access to all critical information in real time. Any archived data can be recalled and visualized at any time. The customizable user interface allows the user to visualize:

- Tube profiles

- Average values

- Production trends

The Lut 2.0 advanced analytics module:

- Detects and quantifies eccentricity orders individually

- Measures the position of heavy/light ends

Maintenance plan

Predictability is key to managing the operational costs of a seamless line. Our service plan gives plant managers the peace of mind of knowing that they’ll never incur unexpected repair costs.

- Flat-rate, all inclusive, 5-year plan

- Insures > 98% industrial availability

Available options

Technical specifications - Lut 2.0 SPP

Wall thickness measurement

Range

3 to 50 mm

0.1 to 2.0 in.

Accuracy

± 0.1 mm for nominal thickness under 20 mm

± 0.004 in. for nominal thickness under 0.8 in.

± 0.2 mm for nominal thickness from 20 to 30 mm

± 0.008 in. for nominal thickness from 0.8 to 1.2 in.

± 0.4 mm for nominal thickness from 30 to 50 mm

± 0.016 in. for nominal thickness from 1.2 to 2 in.

± 0.5 mm for nominal thickness from 50 to 60 mm

± 0.020 in. for nominal thickness from 2 to 2.4 in.

± 0.6 mm for nominal thickness over 60 mm

± 0.024 in. for nominal thickness over 2.4 in.

Resolution

Better than 0.01 mm

Better than 0.0004 in.

Steel grades

Any steel alloys, including stainless

Any steel alloys, including stainless

Tube outer diameter

Range

> 25 mm

> 1 in.

Temperature measurement

Range

600°C to 1100°C

1100°F to 2000°F

Accuracy

± 2°C

± 5°F

Data acquisition

Rate

Up to 100 data samples/sec.

Up to 100 data samples/sec.

Positioning

Any angle along the circumference of the tube

Any angle along the circumference of the tube

Ready to increase plant yield by 5%

Contact us to learn how to leverage the data from the Lut 2.0 and get a return on your investment in less than two years.